DUXTON products are made with the optimum framing material: pultruded fiberglass. Based in Winnipeg, Canada, DUXTON manufactures windows and doors for temperature extremes from -30°C to +30°C, resulting in excellent energy efficiency. The combination of insulated fiberglass frames with warm edge dual, triple, or even up to quint pane glass creates some of the most leading edge systems in the world. DUXTON strives to build products that will last for generations.

The advantages of fiberglass, a material primarily composed of carbon fibers, are evident across a multitude of applications, including marine vessels, satellites, infrastructure like bridges, and protective equipment such as goalie masks. In these various contexts, fiberglass endures exposure to extreme temperatures and persistent wear and tear. Its exceptional durability and resilience render fiberglass windows and doors the superior choice for businesses who prioritize durability, energy efficiency, and design versatility.

Energy-efficient frames with low thermal conductivity effectively hinder the transfer of heat or cold into a building. In comparison to metal frames, fiberglass windows demonstrate markedly lower conductivity.

In extreme temperature scenarios, fiberglass windows preserve their structural integrity, thereby minimizing expansion and contraction to ensure an optimal seal. Given that a substantial portion of a window comprises glass, encasing it with a material such as fiberglass presents numerous advantages, hence the term “Glass on Glass Advantage.” Comprising approximately 60% glass, fiberglass, similar to window panes, exhibits a remarkably low rate of expansion and contraction. This attribute enables fiberglass windows to sustain an excellent seal with diminished movement relative to plate glass.

Moreover, enhanced stability contributes to increased durability, a reduction in seal failures, and improved paint adhesion.

Fiberglass, characterized by an impressive 60% glass content, serves as a premier material largely sourced from abundant silica sand, exemplifies sustainability. The production of fiberglass necessitates only a fraction of the energy consumed in the manufacturing of aluminum, positioning it as an environmentally responsible option.

Moreover, the durability of fiberglass results in a minimal environmental footprint. By investing in long-lasting products such as fiberglass, one not only reduces landfill waste but also supports DUXTON’s commitment to sustainable construction practices that are designed to endure for deccades.

Furthermore, the exceptional energy efficiency and material properties of fiberglass render it a preferred choice for innovative projects, including Net Zero, LEED, and PassivHaus initiatives. It represents a prudent, sustainable option for a prosperous future.

The advantages of fiberglass are extensive; one of the most noteworthy is that fiberglass windows and doors exhibit remarkable bending strength, considerably exceeding that of PVC. This enhanced strength facilitates the creation of slimmer frames and larger glass sections, resulting in breathtaking views with fewer frame interruptions and much wider spans. By opting for fiberglass windows, one can attain panoramic vistas with floor-to-ceiling glass that stretches the complete length of the room, harmoniously welcoming the exterior into the interior living space.

The principal distinction between fiberglass and PVC lies in their rates of expansion and contraction, which significantly influence the durability of both the frames and glass, in addition to the seamless operation of the windows over prolonged periods. Fiberglass windows provide superior energy efficiency when compared to PVC windows, thanks to their exceptional thermal insulation and tighter seals which effectively minimize heat transfer and air leakage, thereby enhancing the overall energy performance of the residence.

Contrarily, PVC may become brittle and susceptible to cracking over time, particularly when subjected to ultraviolet light exposure. Furthermore, there is an increasing movement to eliminate PVC from residential properties due to health and environmental considerations. The “Living Building Challenge” precludes the use of PVC in certified products for the reason that vinyl chloride, which is present in PVC, appears on their Red List of hazardous substances. Duxton offers Declare certified products upon request (https://living-future.org/red-list/), ensuring compliance with these environmentally responsible standards.

For further information, please visit Duxton’s website to explore the advantages of enhanced seals and improved durability.

Fiberglass windows and doors significantly enhance your design options through exceptional color versatility. In contrast to PVC, which generally restricts you to lighter finishes or limited exterior hues, fiberglass provides a multitude of color choices for both interior and exterior settings. Whether your preference leans toward a traditional tone or a custom colour, the robustness of fiberglass permits the selection of any color, whether light or dark, without sacrificing durability.

Fiberglass is recognized as an exceptionally stable material, with a projected lifespan approximately 40% longer than that of PVC windows. Its low-maintenance finish, applied in a manner akin to automotive painting, ensures a weather-resistant and durable surface.

This noteworthy material has been utilized in a diverse range of commercial applications, including recreational facilities, financial institutions, and multi-storey buildings. Its durability has been rigorously tested in educational institutions situated in northern climates, where windows are subjected to both extreme treatment and temperature fluctuations.

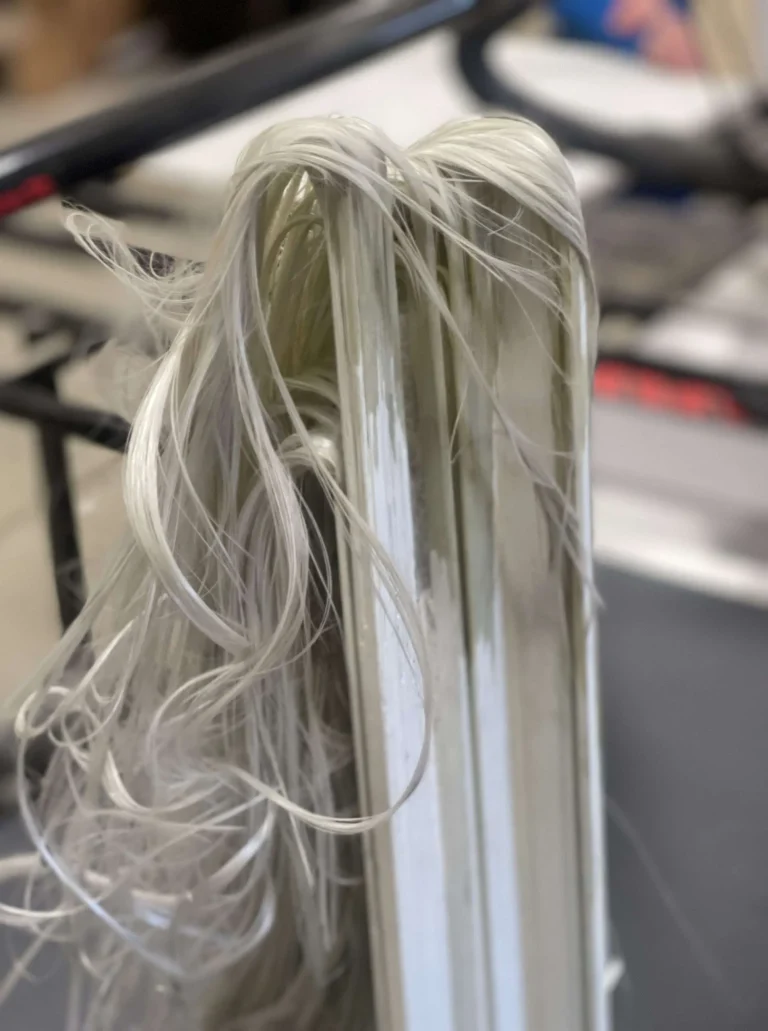

Manufactured from a composite of ultra-strong glass strands and glass matting, fiberglass exhibits unparalleled resilience. The encasement of glass matting around the glass strands aids in distributing impact across the frame, thereby minimizing surface damage. In the unlikely event of surface deterioration, fiberglass can be readily repaired and repainted, ensuring both longevity and sustained aesthetic appeal.

Under extreme temperature conditions, fiberglass windows maintain stability, thereby minimizing expansion and contraction to ensure an effective seal. Given that the majority of a window comprises glass, encasing it in a material such as fiberglass offers numerous advantages, hence the designation “Glass on Glass Advantage.” Comprising approximately 60% glass, fiberglass, similar to plate glass, demonstrates a remarkably low rate of expansion and contraction. This characteristic facilitates fiberglass windows in maintaining an excellent seal with diminished movement in comparison to plate glass.

Moreover, enhanced stability translates to prolonged lifespan, reduced seal failures, and improved paint adhesion.

The inherent stability of fiberglass is essential for ensuring the protection and durability of insulating glass. By demonstrating minimal movement in comparison to both the glass and the surrounding wall, fiberglass window frames significantly diminish the likelihood of seal failure or glass fracture. This enhanced stability not only guarantees the longevity of your windows but also provides reassurance, knowing that your insulating glass is adequately safeguarded.

When it comes to windows and doors, costs can vary significantly based on brand and component quality. Typically, fiberglass windows tend to be more expensive than vinyl options due to their superior quality. However, there are select vinyl brands that offer comparable pricing to fiberglass. Compared to metal-clad wood, fiberglass prices are often similar, though this can vary by brand.

In terms of energy efficiency, fiberglass windows offer notable advantages. Their superior insulation properties and tight seals help minimize heat transfer and air leakage, leading to lower energy consumption and reduced utility bills over time. While the initial investment may be higher, the potential for long-term energy savings makes fiberglass windows a compelling choice for homeowners looking to optimize efficiency and comfort in their homes. Ultimately, the key consideration lies in the value proposition, where fiberglass windows offer not only exceptional design flexibility and durability but also significant energy efficiency benefits.

Fiberglass windows stand out in energy efficiency, outpacing metal options thanks to their superior low conductivity. This quality significantly hampers heat or cold transfer into a building, especially in extreme conditions. For example, in -20°C weather, fiberglass frames outperform aluminum in reducing thermal transfer.

Moreover, fiberglass windows effectively minimize expansion and contraction, ensuring a consistently tight and efficient seal. With approximately 60% glass content, fiberglass mirrors the thermal performance of plate glass, which means minimal movement and enhanced sealing capabilities.

Upgrading to triple-pane windows can drastically enhance the R-value, a crucial metric of thermal resistance. A triple-pane window integrated with two Low-E coatings can achieve an impressive R-value of 7.0, representing only a slight cost increase over a dual-pane window with one Low-E coating, which offers a mere 3.8 R-value.

Additionally, triple-pane windows featuring ½” air spaces, like those from Duxton’s products, boost R-value by 20-30% while also reducing winter condensation. Products recognized as Energy Star Most Efficient commonly incorporate these advantageous air spaces.

Strategically customize Low-E coatings according to the sunlight exposure of each room to maximize energy efficiency. In sun-drenched spaces, a solar-blocking Low-E coating effectively diminishes summer air conditioning demands. For optimal passive solar gain, consider a high solar gain Low-E coating paired with ample overhangs to significantly lessen winter heating requirements. Discover more at Duxton’s Website: Insulating Glass.

By carefully selecting the right combination of materials and glass configurations, you can significantly enhance window energy efficiency and durability.

The price disparity between fiberglass windows and aluminum windows is contingent upon the specific variety and caliber of the aluminum product. Generally, the advantages of fiberglass windows are more cost-effective compared to high-quality thermally broken aluminum windows. Nonetheless, it is noteworthy that fiberglass windows typically bear a higher cost than basic non-thermally broken aluminum storefronts.

Despite the initial investment, fiberglass windows provide substantial long-term operational cost savings attributed to their exceptional insulating properties, which significantly enhance energy efficiency and mitigate heating and cooling expenses over time.

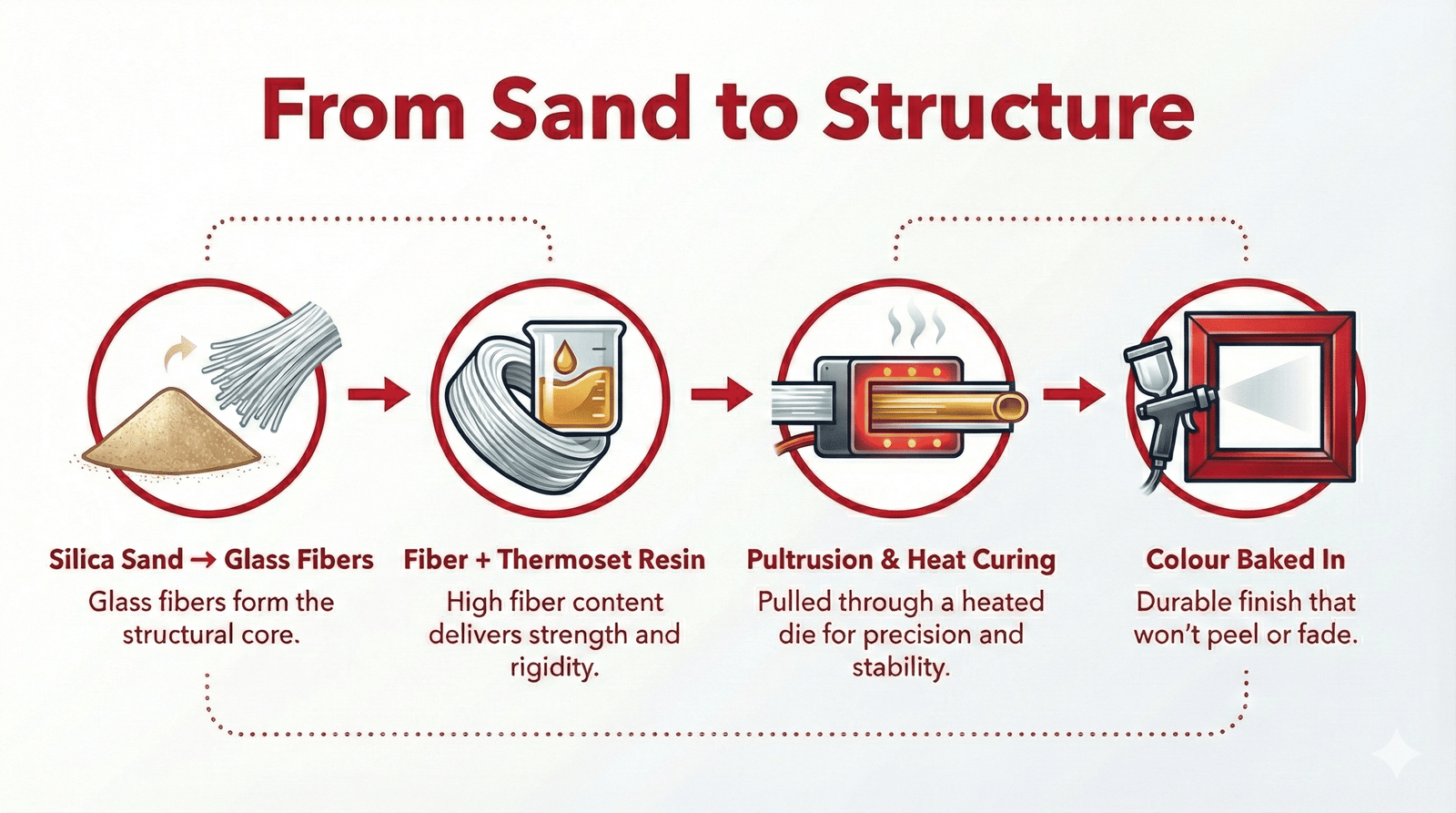

Precision engineering at every stage—from raw silica to performance-ready window and door frames built to last.

Production commences with silica sand subjected to extreme heat, creating continuous glass fibers through a specialized drawing process. These fibers establish the core structural framework of every Duxton fiberglass frame.

High-density glass fibers undergo fusion with thermoset resin, producing a composite engineered for superior rigidity, thermal performance, and dimensional consistency. This fiber-rich composition delivers performance characteristics that surpass both vinyl and wood materials.

The composite material advances through heated precision dies in a continuous pultrusion process, achieving high-temperature curing. This manufacturing method ensures consistent cross-sectional dimensions, tight tolerances, and long-term shape retention.

Color integration occurs throughout the material matrix during production rather than as a surface application. This integral pigmentation approach provides exceptional UV resistance and permanent color that never requires painting or refinishing.

This engineered manufacturing process enables Duxton fiberglass frames to deliver consistent performance in extreme weather conditions and modern building designs.

This series includes a Lo Profile frame, allowing for maximum glass area, and a Hi Profile frame, matching the sight lines of an operable window.

Casements and Awnings are the most sleek-looking, highest performing venting windows available today. Provides excellent air tightness and thermal performance.

Duxton’s Sliding Doors maximize your floor area by not having panels swinging into the room or out onto your deck. With a sliding screen, the door also allows for lots of fresh air. Extra large sizes are available to bring the outside in, and open up your space with natural light.

Make a statement with your doors. FiberWall™ Swinging Doors can project any style, with amazing size capabilities and finish flexibility. With a rigid insulated fiberglass frame, a high quality fiberglass panel, and even multi-point locks, FiberWall™ delivers excellent thermal performance and durability.